Archive for the ‘Lab Projects’ Category.

23rd December 2016, 10:37 pm

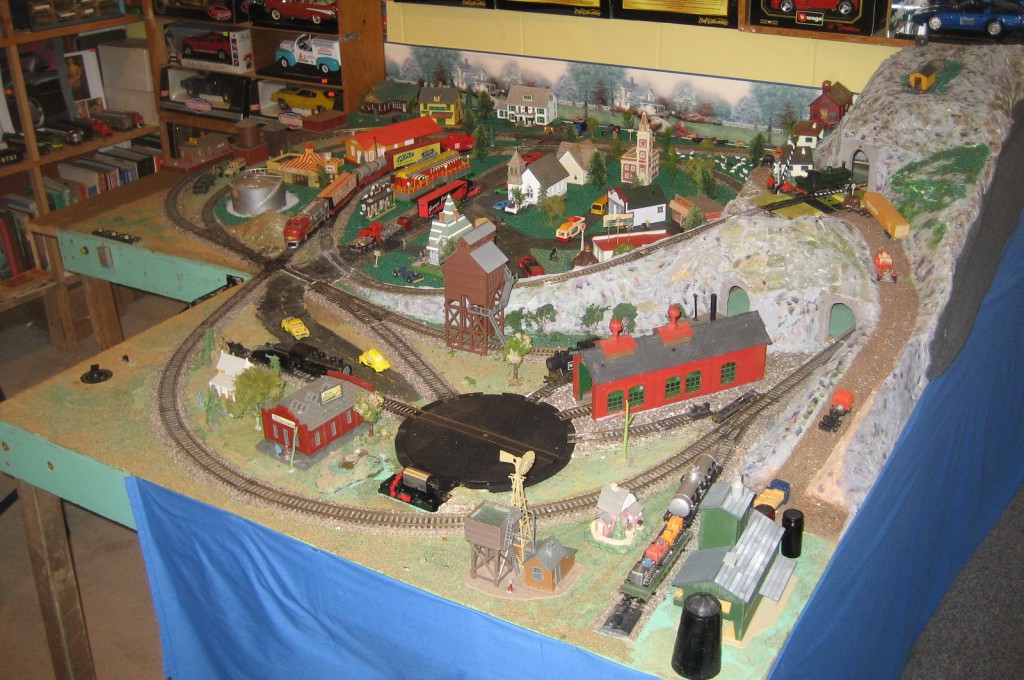

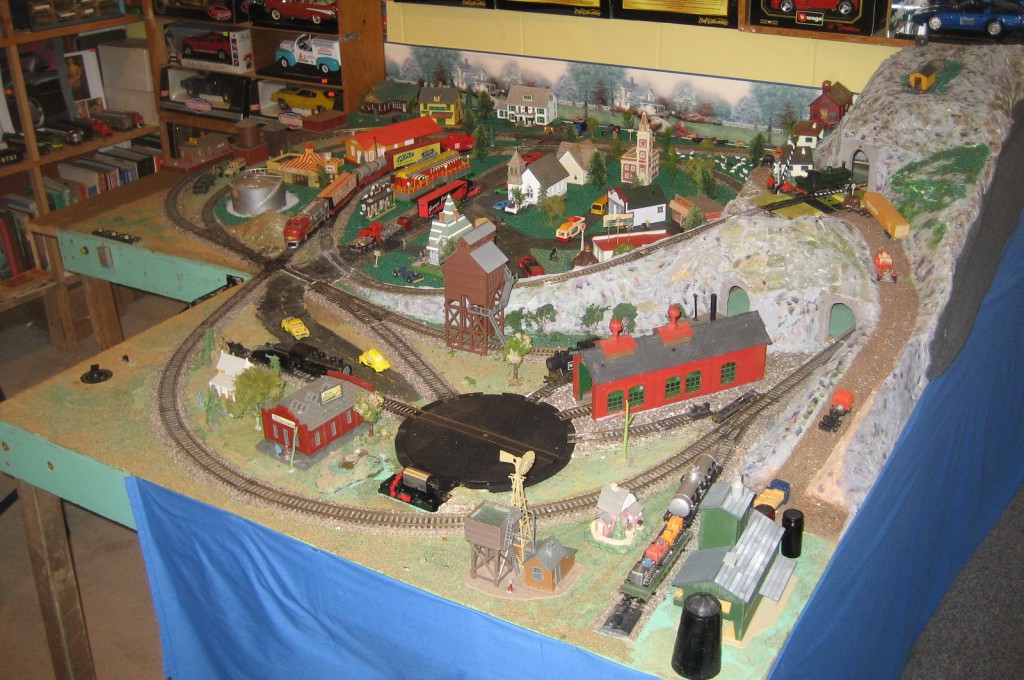

The pictures below are of the old HO train I set up recently in my shop. In my youth I liked trains. In 1946 I received a Marks wind-up O scale for Christmas. In the early 50’s I started building HO model kits. My brother sent me two Japanese brass locomotive kits when he was in Korea during the war. About 1980 my son and I acquired a incomplete HO setup at a garage sale. We got it rewired so it ran and he built, decorated and arranged things. It was sharp looking and took up a big part of the spare bedroom. A few years after He graduated from college and no longer lived at home, the train was packed up and stored in a farm shed. Now his youngest son has a strong interest in trains. I dug out the old board with the tracks on it and rebuilt the set up so my Grandson, Gunnar, can run it. below is the picture of it.

It was a time consuming job setting it up, but it was fun. Electrical connections age and get dirty along with everything else. Me, I build and fix things, but My wife, Donna, does all of the painting and decorating, for she is very artistic. She picked a lot of things to use that we had. You can see in the picture that Santa Clause is even there for Christmas.

We found lots of fun stuff to put on the board. We had acquired treasures at garage sales and auctions over the years.

The picture below of the Cheerios store is an old treasure of mine. It was from a Cheerios box in the middle 1950’s. After I ate all the Cheerios as fast as I could, I cut out the store from the empty box, folded it out and glued it together. It brought back lots of memories when I found it.

One last Picture, it is of the flock of sheep my wife put in the pasture. We have had a lot of fun with this project. My grandson, who is eleven year old, has enjoyed it very much. He has suggested that I should add more track and area to the set up. His suggestions have made a lot of sense. If it is a cold winter and I spend a lot of time inside, who knows what will develop.

My Sheep on Pasture

3rd April 2015, 11:28 am

This is a different kind of spring here on the prairies of Minnesota. The last two days were warm, temp up in the 60’s and 70’s. The winds started from the south on Wednesday AM with gusts coming up to 40 MPH by afternoon. The wind shifted to the west by Thursday with gusts in the high 40’s by afternoon. The wind would come in gusts that would shake the trees in my yard and farm grove. Clouds of dust would swirl across the bare fields some times moving cross ways to the regular wind. My Wife and I sat for a time on the porch watching but when the dust swirls came it would make your eye water and cover everything with a fine layer of dust. That does give your coffee a different flavour so we retreated to the inside.

I will have a couple of days of work picking up the tree branches laying on the lawns and in the farm grove but experts say exercise is good for an old man.

5th December 2013, 08:59 pm

The Sun Dog is Out

The snow came yesterday on the Minnesota prairie. It was mild at first and snowed heavily. As the day went on it got colder and the wind became stronger. It was beautiful to see everything white. By late afternoon the snow fall lightened so it was just flurry’s, I then cleaned 6 maybe 8 inches of snow off my driveway. The wind had become strong and it was not comfortable out side as it became dusk.

This morning the sky was clear out and a beautiful blue color. The temperature was at 0 Fahrenheit and the wind was still gusting to 35 to 39 MPH. It was so beautiful outside I just couldn’t stay indoors.

The bright light to the right of the sun in the picture, we always called a sun dog. They would be seen one on each side of the sun when it was very cold and clear out. I learned that they are caused by the reflection of ice crystals in the air. I couldn’t resist taking a picture because they were very bright today.

The road in the picture runs due south. You can see how low the sun is in the south. It was a Little after 11:42 AM when I took the picture.You can see High Noon doesn’t happen here this time of year.

Also note how the fields have been swept almost bare in spots by the strong winds. I am standing in the windbreak on the East side of my large farm grove, so the snow is not drifting close to me. The wind is from the Northwest and you can see down the road where the snow is sweeping across where the windbreak ended. Yesterday afternoon the trees had been loaded with snow now they are clear. I started to walk to the west side of the farm woods. As I got closer to the windward side I had to turn back. The snow had piled in deep and I hadn’t dressed warm enough to bear the cold wind. I went back inside, so thankful I don’t have to work out in this anymore.

3rd October 2013, 08:51 pm

This hot summer I have been lazy. After taking care of the yard and things there wasn’t much energy left. By the afternoon I was most comfortable in the place shown in the picture.

Easy Living

Now that fall is here I am back to doing a few Projects. Below are pictures of my old hog barn that I turned into a storage building. I had cleaned it extensively with strong detergents and a high pressure washer. It was fine at first but this spring and summer the aroma of hogs came back slightly. Checking around, the most probable cause was that concrete holds odor deep inside itself. I was advised that sealing the surface was the best cure.

Now it is a fact that I am some what of a pack rat. I just hate to throw anything away that might be usable. I had on hand a large amount of paint some of which was quite old. Some had come from a household auction of a retired painter friend in the 1970’s. My Father-in-law and I helped by bidding on piles of paint. My Father, Father-in-law and I used much but still I had many cans left. Plus one always has other odds and ends left over.

The following solved two problems. Because it was a storage shed the colors on the floor didn’t matter. The cement floor was very porous and eroded so it would soak up a lot of paint as you can see in the picture below.

The Old Floor

Donna At Work

I eliminated 20 quart cans and two gallon cans of paint. I started with cans that were rusty or had the labels missing. A few were hardened beyond use but most stirred up. chunks were used to fill holes where anchor bolts had been ripped out when we removed gating and partitions. I was amazed at the amount of paint that soaked into the floor. The raised walkway on the left used up the whole gallon of tan I received free at a garage sale I stopped at that was just closing.

The colors were found at random and my intention was just to cover the floor but my wife came to the rescue and turned it into something quite unique. Best of all the building smells fresh again and where I store paint in my shop has much more room.

Wild Floor

The Finished Floor

4th January 2013, 04:36 pm

27th December 2012, 11:29 am

Over the years the old farm has collected stuff. Everything was saved that might be usable later. The last years I have been working to clean up the place. Metals need to be recycled, saleable things need to find there way to people that have a use for them. I also look for things that tell me more about my brother, my father and my grandfather.

The picture on the left shows the old truck van body my brother brought out here in the early 1970’s. Dad owned the farm at that time, and Phil, who worked in St.Paul, needed a place to store good stuff. It was full of all kinds of car, truck and old tractor parts. There were also old tools and farm things. By the time I bought the farm from Dad, the farm grove had grown thick around not only the old Van, but around the junk cars, old tractors and machinery. It was barely visible so it made very little difference.

What was a good, weather tight storage unit had deteriorated over the years. My brother had also aged and lost both interest and energy to do anything with it, so it mainly sat undisturbed for the last 25 years. The last ten years I kept a plastic tarp tied down on top to keep rain out. My brother thought that his sons would want all these good things. I remember the disappointment on his face when they stood here telling him there was nothing in there that they wanted. When My brother passed away, I became owner of all that good stuff.

Over the years we have cleaned up the farm grove. Cutting up the dead and broken trees. Removing Buckthorn and planting grass. This made the Junk an eyesore, so one of my main retirement projects has been the clean up. This fall with my hog barn converted to good storage I started the Van clean up. The next picture on left shows the inside of the van when I had it mostly empty. I regret not having taken more pictures. The Van was so full you couldn’t tell what was at the far end. It was a bigger project than I anticipated. Plastic pails, full of bolts and parts, turned to almost dust as you tried to move them. Cardboard boxes did the same. Field Mice had had a good home in there and years of dirt and dust had blown in. The wood floor of the Van had rotted away in places so carrying heavy things out was a bit touchy.

I was never sure what was all in there so I turned down an offer from a scrap iron dealer to just haul it away.

I hauled trailer loads to my shop, blew the dirt off with my air compressor, and then sorted things. I didn’t find much good stuff, but it was an interesting project. Most things needed cleaning either with the wire wheel or the sand blaster to be sure what they were. Than copper, brass, iron, aluminium all needed to be sorted for scrap. Because time was slipping by, some bigger thing were just cleaned off and moved to storage to be dealt with next spring.

Many thing that had value once, were now deteriorated beyond use or just obsolete. Old bolts had always been saved because they were useful for fixing old farm machinery. Now they were rusty and of sizes that I will never use, so on to the iron dealer. I handled the small iron scrap by putting it in cleaned out empty one gallon paint pails. The small stuff could be shaken down tight, than the cover hammered on. This made handling easier, preventing the scattering of old nails and stuff.

These last two pictures show the inside of my storage building. Hub caps have been hung on the wall for decoration. Also you can see the tail of Dads old wind generator from the 1930’s. We had no electric power on the farm, so the wind was used to charge a spare car battery so we could have radio.

I still have much to deal with yet but I am making headway. Next spring all the old tractor parts will be gone. Where the van body stood will become lawn again.

19th December 2012, 09:27 pm

Back in 1979 I had this Hog Barn built. It was state of the art, a well insulated building, automatic fans, augers to fill the feeders and feed in steel tanks that mice or rats could not get to. Slatted floors kept the hogs clean and liquid manure handling ended the day of the man with a shovel.

I did well at first, but times changed. This system allowed farms to grow large and raise huge numbers of hogs. So profit margins got thinner and thinner. I had no desire to grow bigger and bigger, even though my banker recommended it. By the time I got the building paid for I rented it out. Nothing lasts forever and time took it’s toll on the building and equipment. By 2008 the building was too small to be worth the high cost of renovating. You can see the deterioration in the photos. Normally the renter would pressure wash the inside of the building after every batch of hogs were sold. My thought at the time was that the building would be buried so washing was pointless. I sold the feed tanks right away, as they were still quite valuable. you can see in the picture that the tank is gone but the buyer did not bother to take the augers or even the fittings on the bottom of the tank. I waited a year and one half for the buyer to come back for the rest of what he paid for but it never happened. I guess he figured he got a good enough deal on the tanks and he didn’t need the other old junk.

small to be worth the high cost of renovating. You can see the deterioration in the photos. Normally the renter would pressure wash the inside of the building after every batch of hogs were sold. My thought at the time was that the building would be buried so washing was pointless. I sold the feed tanks right away, as they were still quite valuable. you can see in the picture that the tank is gone but the buyer did not bother to take the augers or even the fittings on the bottom of the tank. I waited a year and one half for the buyer to come back for the rest of what he paid for but it never happened. I guess he figured he got a good enough deal on the tanks and he didn’t need the other old junk.

At that point I advertised the augers and motors on Craigs List. A couple of young fellows from up north responded. We laughed and talked and dealt. They left with all the remaining equipment.

The next big problem was the many yards of cement walls that divided the hog pens. They were 42 inches high and poured in place with steel reinforcing. I tried to remove them by hand but they were built well. After several hours of work with little progress I gave up. I didn’t know what to do next.

The next spring The Wife and I decided to have our driveway paved to keep mud and dirt out of the house. The contractor was a local fellow, knowledgeable and friendly. In the course of visiting with the fellow, the Hog Barn came up. I showed him the project, and explained my inability to remove the cement partitions. He smiled and said, ” make a way for me to get my skid loader in and I will have them out in a couple of hours”. With a little help I cut a hole in the wall where a garage door would someday be and we were on our way.

I wish I had taken pictures of the process. The jack hammer mounted to the front of the skid loader cut the cement like butter, it was amazing. Then the pieces were stacked outside in a big pile. Two days later they were hauled away for recycling. What I had considered the most difficult job turned into the easiest.

I swept and cleaned some, but other projects took president. This spring I became determined to complete this project. I pulled my old pressure washer out of the back of my shop where it had been sitting for a few years. Cleaned it up and checked it over and it worked fine. I even found the strong detergent that I have had tucked away for 15 years. First I shut the electric power off to the building and then began washing. Wash it, let it soak, hit it again, let it soak again, than rinse it. I worked on this several different days, because I every time I would came back I would see spots I had missed.

On your right you can see the rough cement where we cut through the wall. I learned to use a masonry cut off blade in my skill saw and a masonry grinding wheel in my hand grinder. You can see in the left picture that they do a nice job. The dust from these tools is hard to tolerate. The hot weather made my dust mask uncomfortable but the head ache and cough that came if I didn’t wear it was much worse.

Slowly the project moved on. There were many little things to fix, as time and moisture had taken its toll. The sloping floor where the garage door opening had been cut was a problem. Also the structure of the building limited the space available for a garage door. Plans had to change as I went along.

Slowly the project moved on. There were many little things to fix, as time and moisture had taken its toll. The sloping floor where the garage door opening had been cut was a problem. Also the structure of the building limited the space available for a garage door. Plans had to change as I went along.

The picture below and on left shows where the particle board in the wall under the plastic wall covering had rotted away. What I found surprising was the condition of the insulation. The walls had been filled with six inch bats of fibreglass. Where ever I opened the walls, the insulation was like this. This makes me wonder about insulation in my house walls. Most repairs were fairly simple, they just took a lot of time. I used up much lumber that I had tucked away.

The walk in door and frame on this end needed to be replaced. I had an old door I had salvaged but there was no Knob or latch for it and its frame was damaged. I lucked out, Habitat for Humanity’s thrift store had a complete door set up for a bit less than 30 dollars. That was cheaper than the cost of a new knob set. The picture on the left and below is the door installed, not bad for a barn.

On the right is a picture of laying of the floor. The Barn had a cement slatted floor with a pit for manure under it. Exhaust fans pulled fresh air through the slats and blew the smelly air outside. I had cleaned the pit, but the old smell was still there. I didn’t want to run fans all the time so I did the following. I used roofing sealer and tar paper, then covered the slats with particle board. I used two layers with overlapping joints and screwed them together. it is an air tight floor.

On the right is a picture of laying of the floor. The Barn had a cement slatted floor with a pit for manure under it. Exhaust fans pulled fresh air through the slats and blew the smelly air outside. I had cleaned the pit, but the old smell was still there. I didn’t want to run fans all the time so I did the following. I used roofing sealer and tar paper, then covered the slats with particle board. I used two layers with overlapping joints and screwed them together. it is an air tight floor.

notice the walls are rusty red from the cooling sprinklers that were run on hot summer days. compare that to next pictures of the finished inside. My wife removed them all with toilet bowl cleaner, A big improvement.

These two pictures show the project which is pretty much finished. It makes a good storage building. clean and nice inside. At 26 by 56 feet it is a lot of space. I plan to add some more shelving for small stuff. Many things can be hung on the wall like the old hubcaps.

Below is the finished outside

11th December 2012, 02:29 pm

An old fashioned blizzard came last Saturday and Sunday. First warm moist air blew in from the south and ran into the cold air coming from Canada. The snow came down heavy and the wind blew hard from the South East. Then during Sunday the wind switched to the North West and gusted up to 35 MPH. We were lucky they had predicted gusts over 40 MPH. The temp dropped through the night to 8 below 0 Fahrenheit. You won’t last long outside in weather like that. The good thing is the dropping temperature ended the snow.

I stayed in mostly, took a few pictures outside, and checked that everything was OK. I can’t take the cold like I used to.

It brought back memories of the days when I was a boy. Storms were exciting, if they came during the week you would have days off from school. One of the best things was I was allowed to stay up as late as I wanted. The whole family would be home and during the storm, outside work was held to a minimum. Often we all sit by the kitchen table and play games, read by the gas lamp or just talk.

The wood fire in the kitchen range would be burning at maximum. The draft damper on the back of the stove would click as the wind gusts swept by the chimney. The sound was fascinating, a regular tapping that was completely random. It was like a strange kind of music. I don’t think anyone else ever paid attention to that sound.

In the 1940’s the road through the farm was the main north south highway. It connected the two county seats , Willmar and Olivia. I can remember having people snowed in for the night. The one I remember best was a fellow with a grocery delivery van. He had become stuck on the road by our farm grove and dad pulled his van in the yard with his team of horses. It was war time and many things were rationed. All the fruit and food that could be damaged by freezing were carried into the house for the night.

He was outgoing and full of fun, with a loud laugh. I was given bananas, cherry’s and other goodies to eat, and he encouraged me to eat more of what I liked. When dad would remind us that we should be conserving these good things, he would laugh and say it would all have been lost in the cold if it wasn’t for you, so enjoy. I remember the laughing and talk going on into the night. I think I fell asleep in my mothers lap, I don’t remember. When I awoke the next morning, the storm had ended, the snow plough had come by, and the fellow had left.

Below is a picture early Monday morning. The sun was shinning bright, the air is clear and cold at a minus 9. I always remember it being beautiful after a blizzard. My sister and I would take the sled or shiny scoop shovels and slide on the new drifts.

The work horse’s would be so happy to run free in the barn yard even if it was cold, after being cooped up for a couple of days. They would run,jump, buck and pass gas noisily.

It is so beautiful outside. Sparkling white in the bright sun. One could feel a bit of warmth from the sun and a crisp cold from the air. We had 15 inches of snow but it never lays still on the prairie. The next picture shows my farm field, you can see soil showing through the snow cover. The wind has swept the snow into farm yards, fence lines and road ditches. When the wind blows from a different direction the snow will move again.

I have two more pictures to show. The first shows a job for me . the snow flying off the snow plough lays the mailbox down often. Not serious, just a bit of work, worth it to have the road open. The second one shows why we had a quiet time during the storm. That little amount of snow that stuck to the dish, blocked the TV signal from the satellite very effectively.

30th November 2012, 11:17 am

The spring, summer and fall went fast. The beautiful spring turned into a hot summer. Then came a nice fall with all its colour’s, now this has disappeared.

I took pictures this spring of a quick little project I did. I planned to put it in on the web site then. I tend to spend little time at the computer when the weather is nice outside so I just never got around to it. Now it has turned colder outside, so it is more comfortable by my computer. I will now show them to you.

The mower deck on my old Yard Man lawnmower tractor failed a year ago this fall. The unit is 10 years old and I mow a large area. The repairs would have cost over half of what I paid for the unit new. So I replaced the unit with a new John Deere garden tractor-mower unit.

We started using it to pull the old trailer in the picture. We hauled yard scraps and leaves out to the compost pile in the back part of the farm grove. Soon we were using it to haul many things around the large farmyard. My Wife and I both found it handy as we left it hitched to the trailer. Without the mower it was easier to get off and on. The only problem was it was very difficult for two of us to ride on it.

As you can see I solved the problem with a few hours work and stuff I had around the farm.

It was simple as the original seat was held to a flat bracket with two bolts. This kept the original spring system in place for a nice ride.

The cost was nothing, as I used stuff I have saved. A couple of pieces of 3/4 plywood I have had for years. some left over foam rubber and vinyl upholstery material. Rummaging through my salvage iron found the pieces I needed to make brackets to hold the backrest.

As you can see I had to double the brackets around the bend for strength. I did maintain some spring in the backrest however.

Donna came to my aid with here skill and creativity. she did the upholstery work and I think it turned out looking very good.

I did run into a bit of a problem with the mower lift lever and the shift lever. They both stuck up too high and interfered with the seat.

I fired up my old acetylene welding torch that I purchased in the early 1960’s. Although not used much in this day and age, it cured the problem easily, as you can see by the next two Photos.

The mower lift handle could have been removed as it is unused but this was simpler. You never know I may figure a use for it down the road.

The next picture shows Donna and My Grandson Thorwald. He and his brother Gunnar both enjoyed driving around the farm. The seat allows them to learn to drive safely and to enjoy giving Me or Grandma a ride. Donna and I have both enjoyed using my customised garden tractor.

Summer 2012

2nd January 2012, 12:22 pm

I spotted a piece of foam and put on the bottom. That way I didn’t have to clean up the J B Weld I had over most of the bottom. It also keeps the rest from scratching the desk surface. The rest now stays firmly in one place but is also easily moved. No more tipping over when you bump the cord or Iron. A simple fun project making use of junk.

I spotted a piece of foam and put on the bottom. That way I didn’t have to clean up the J B Weld I had over most of the bottom. It also keeps the rest from scratching the desk surface. The rest now stays firmly in one place but is also easily moved. No more tipping over when you bump the cord or Iron. A simple fun project making use of junk.