Sharpening a Reel Mower

Classic reel lawn mowers fell out of fashion in the 1960s as internal combustion engines became inexpensive. As gas hovered around $0.19 a gallon, the advantages of the rotary-blade mower far outweighed the labor-intensive reel mower approach.

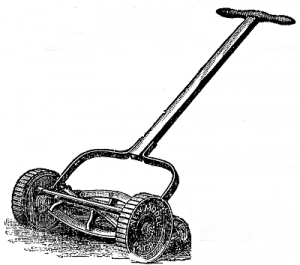

What’s a reel-mower, you ask? One of these:

Most people under the age of forty have never even seen one of these in person, but with gas hovering around $4/gallon, they’re starting to come back into fashion. How does it work? That drum in the center rotates, and cuts the grass against a bar (not visible in this picture). The reel’s blades must just barely contact the bar, and the grass is cut as surely as if you used a pair of scissors.

What are the advantages of the rotary-blade mower as opposed to the reel mower? The rotary blade mower will cut ANYTHING. Sticks, weeds, dandelions, fingers, you name it. Why? It’s got a blade that weighs between one and five pounds, rotating at a few hundred RPM. Just like a helicopter rotor, it slices things off. It hits dandelions and slices them before they have a chance to lie down. The reel mower does not do this — dandelions tend to lie down and pop up again after the mower has passed. The reel mower also jams when it hits a stick.

Any fool with a bench grinder can sharpen a rotary mower blade. Nevermind that the rotary blade has so much power that it doesn’t really NEED to be that sharp. The reel mower must be precisely adjusted and sharpened annually. The average hardware store will sharpen a rotary blade for $5-$10. Hardware stores that still sharpen reel mowers do so for upwards of $50. Most rotary mower owners change the oil in their machine every few years (even though they should do it annually). Reel mowers should have their gears and bearings repacked with grease annually.

Fairly clear why the rotary mower won, isn’t it? Gas, however, is now twenty times as expensive as it once was. America is fatter, and needs more exercise. People are starting to be concerned about greenhouse gas emissions, and some people even like the quiet action of a reel mower (they are far more quiet than a rotary mower).

The rub now is how to sharpen a reel mower, particularly since most hardware stores won’t do it. Those that do have a special lathe rig to put a crisp edge on each of the curving blades. In theory, a person with a metal file or whetstone could do that manually, but it is exceedingly difficult. One could also drill all the rivets out of the blades, and run them across a bench grinder, too. Seems like a lot of work, doesn’t it?

Forty years ago, however, MNDOT mechanics had (and presumably still have) a much easier system for sharpening these things. Run the blades backward and let them sharpen themselves.

For this project you will need:

- an electric drill which can be rigged to run unattended

- valve grinding compound

- a small quantity of used oil

- a pan to hold the oil compound

- a piece of garden hose

- two hose clamps

- properly sized wrenches

- old paintbrush

- reel mower (obtained from neighbor’s garage sale for $3)

- patience

Once you’ve accumulated these tools, you’re ready to sharpen your reel mower. AT ALL TIMES YOU MUST BE AWARE OF WHERE YOU ARE PUTTING YOUR FINGERS! THIS RIG WILL HAPPILY CRIPPLE YOU.

- remove the handle from your mower. When you’re done, it should look like this:

- Place the pan under the mower

- Adjust the reel so that the blades are just touching the striker bar. You should be able to run the mower backwards with mild effort.

- Remove one wheel of the mower, to reveal the drive mechanism

- Using your length of garden hose, attach your drill to the drive shaft of the mower. We put a metal cylinder inside the drill and tightened the chuck, then slid the garden hose over the the drive shaft and the shaft protruding from the drill. Tightening the hose clamps prevented the hose from turning freely. This picture shows our initial attempt without hose clamps:

- Brace the mower so that it will not rock forward or backward. We used a piece of 2×4, with three-inch drywall screws to hold it on place:

- Mix grinding compound with enough used motor oil to make a slurry. Here, an old medication bottle is used as the mixing container:

- Brush the compound along each blade as the mower slowly rotates backwards:

- Begin the counter-clockwise rotation of the mower, and tighten the striker bar so that you hear a scissors-like sound. The blade doesn’t need to turn terribly fast. Here’s a short video of the initial experimentation with speed: Reel Mower Sharpening Video 1

- Set cruise control for 55 mph…errr, set the reel to rotate at a reasonable speed, and remember to put fresh compound on the blades every fifteen or twenty minutes. You’ll also need to be adjusting the striker bad to continually come in light contact with the reel. As the blade approaches razor-sharpness, you will hear the sound of the rig change, as evidenced in this video: Reel Mower Sharpening Video 2

- How long should you do it? The blades should be shiny and smooth on the edges, and the striker bar should have a nice shiny bit on it, as well. We ran it until our adapter rig failed, which took about two hours:

- Reassemble your mower, and enjoy a more environmental mowing experience.

The nuts and bolts on this particular Craftsman reel mower were all either 9/16″ or 1/2″, and there was a mix of hex and square-head. The wheel was held on with four #2 philips-head screws.

Of the two hours that this mechanism ran, it probably took a total of twenty-five minutes of actual labor to sharpen the blade. The rest of the time, the reel was spinning backwards, and the staff of LightningRodLabs was yammering on about various other projects. At one point, the mechanism was left to itself for forty minutes while the staff ate some lunch.

Wear old clothes when you do this — the rig likes to spit oil/grinding compound mixture in small, black droplets.

LabFiles at LightningRod Labs » Blog Archive » Sharpening a Reel Mower:

[…] Okay, maybe we drink beer while we’re doing it, too. Regardless of that, for 2008, we decided to document the easy way to sharpen a reel mower — potentially saving you $60+ over a professional sharpening, while still making the mower every bit as sharp. Click here for more. […]

16 June 2008, 11:38 am